|

||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||

|

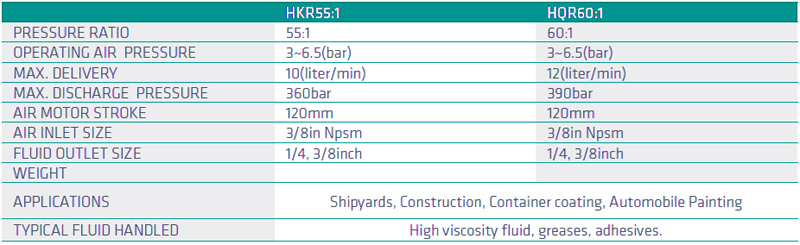

1000Lit. Dual Ram SEALER & PVC CENTRAL SYSTEM________________________________

This system is including central and booster pneumatic pumps. |

||||||||||||

|

Pump With Single & Dual Post Ram___________________________________

Pumps With Dual Post Ram Equipted with electrical heater_____________________

Pumps With Change Over System Dual Post Ram Equipted with electrical heater_____________________

|